Apollo 13’s Lifeboat Fifty Years On: Remembering Grumman’s Lunar Module and Program Director Joe Gavin

I saw the movie Apollo 13 with him. Now let me tell you the forgotten story of how he and his team helped rescue the astronauts while the world watched and waited…

Andrew S. Erickson, “Apollo 13’s Lifeboat Fifty Years On: Remembering Grumman’s Lunar Module and Program Director Joe Gavin,” China Analysis from Original Sources 以第一手资料研究中国, 15 April 2020.

Click here to read companion post on semicentennial of Apollo 11 moon landing.

Four-part Twitter-thread summary:

- Remembering what the movie Apollo 13 forgot to include: The legacy of Lunar Module Director Joe Gavin and his Grumman Team.

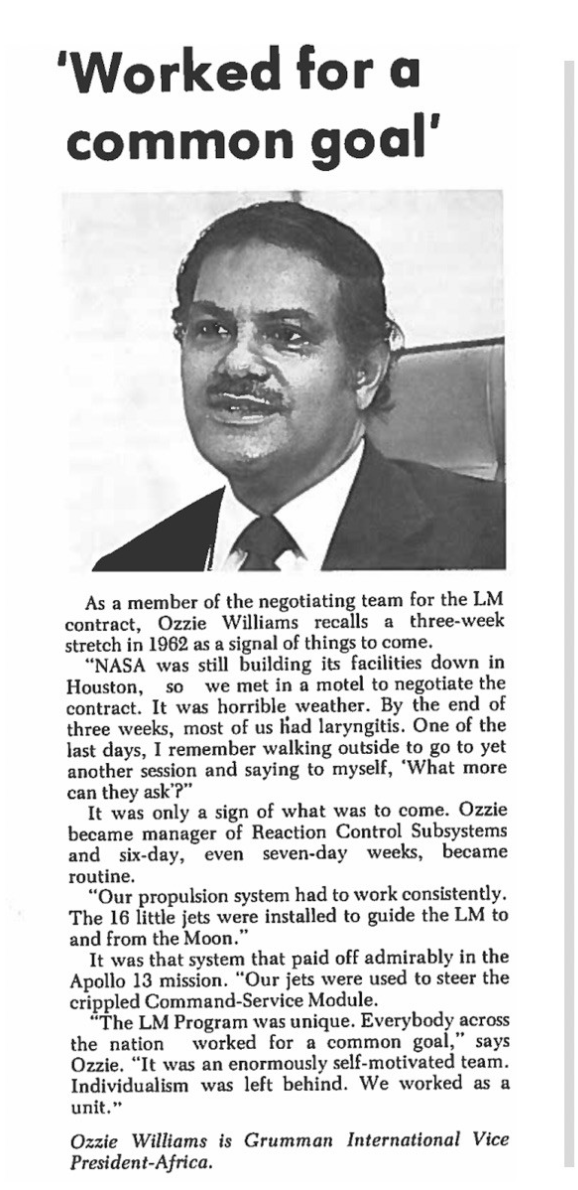

- Reaction Control System Project Leader Ozzie Williams’s pioneering career and contributions to the Lunar Module’s rocket thrusters, which helped steer Apollo 13 safely toward Earth.

- Picturing those behind the lunar lifeboat rescue with key photos: sources and significance.

- Reflecting on Grummanites’ finest hour fifty years ago and Gavin’s career and conclusions.

APOLLO 13’S LIFEBOAT FIFTY YEARS ON:

REMEMBERING GRUMMAN’S LUNAR MODULE

AND PROGRAM DIRECTOR JOE GAVIN

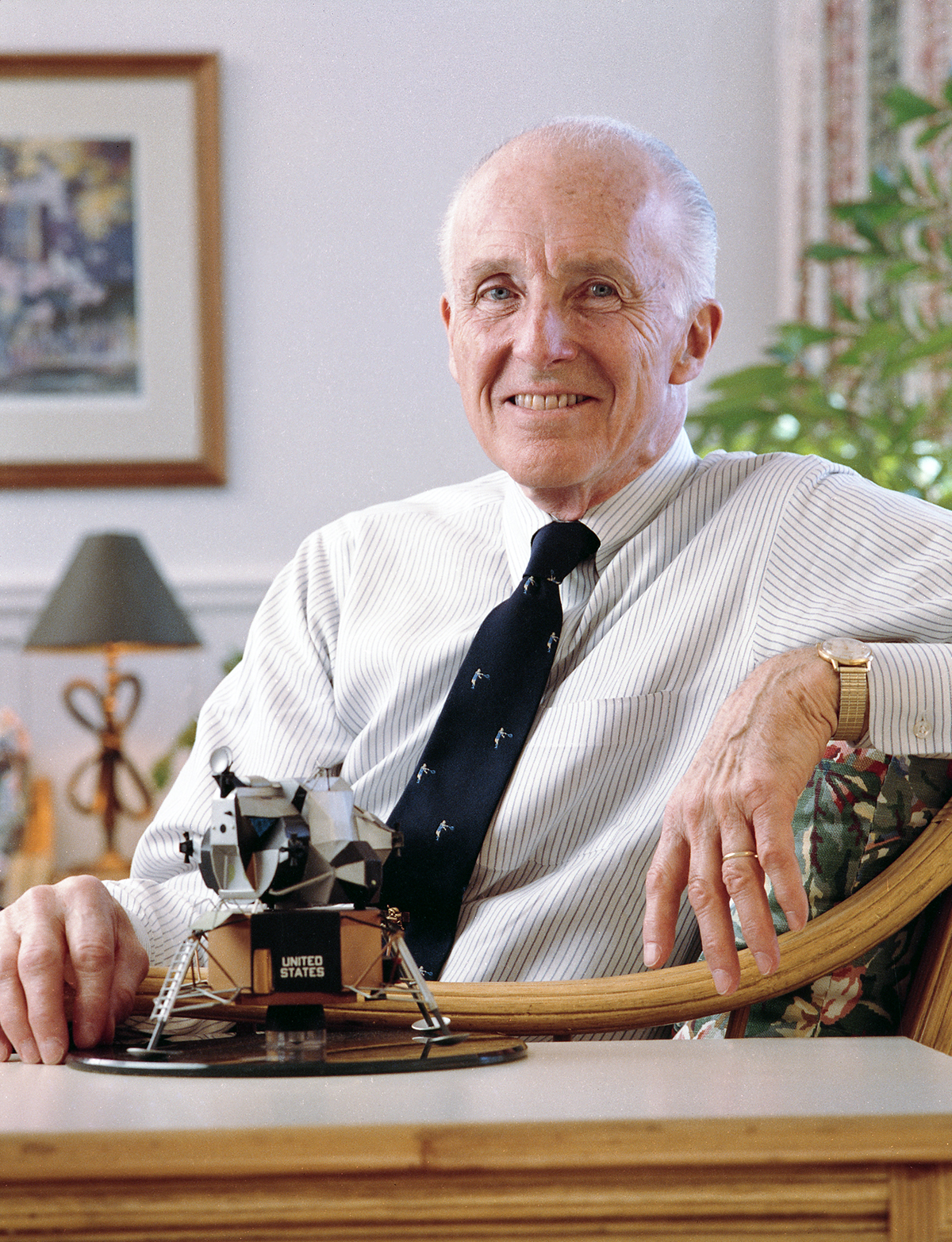

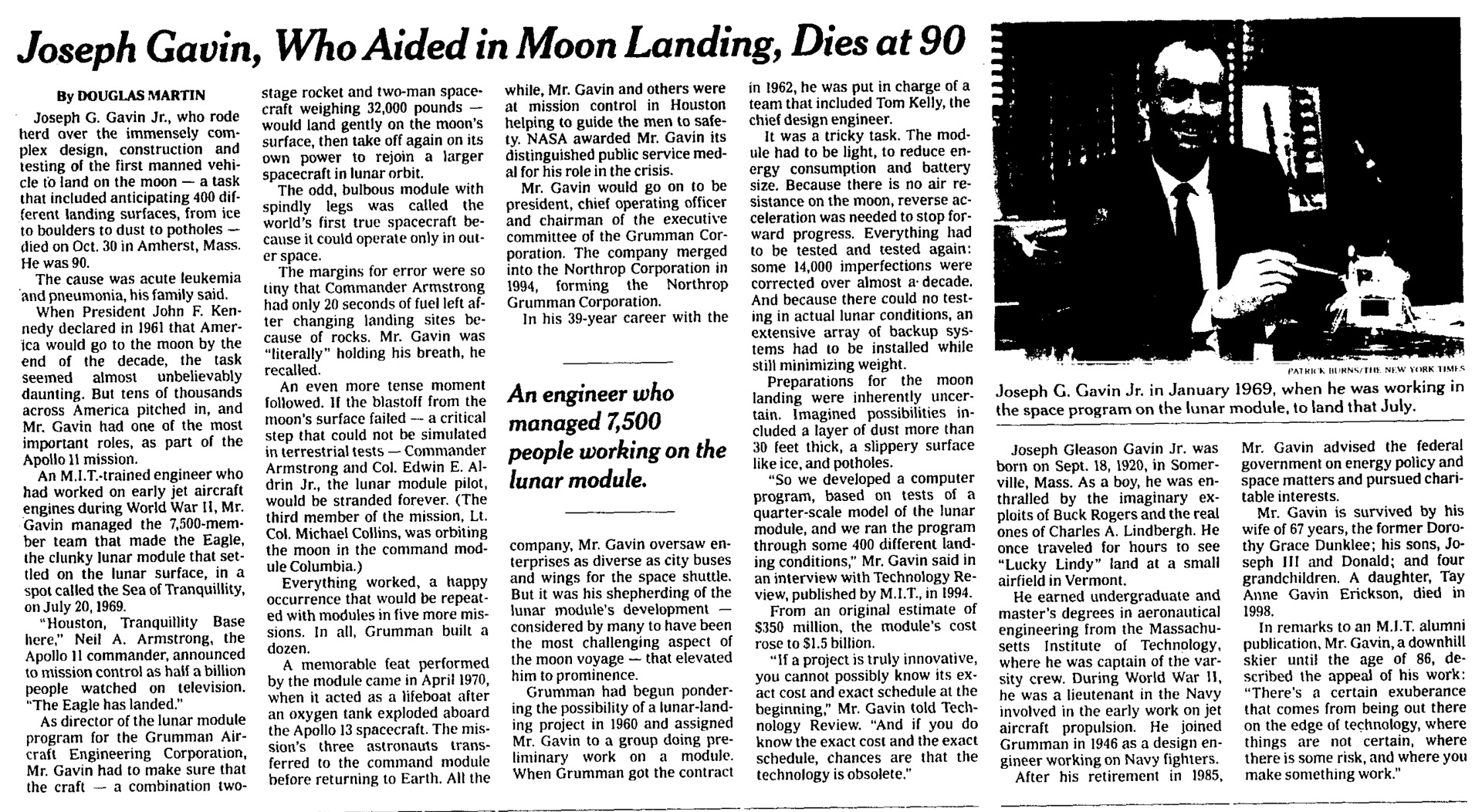

Five decades ago, during the aborted Apollo 13 mission of April 1970, the Grumman Aerospace Corporation’s Lunar Module (LM) saved three astronauts by becoming a lifeboat and tugboat. Throughout the crisis, LM Program Director Joe Gavin manned his post in NASA’s Houston Mission Control Center, helping coordinate the urgent assessment and application of the LM’s capabilities for this emergency assignment. Gavin, virtually all of his colleagues and contemporaries, and Grumman itself, have subsequently departed from the scene. Recent popular commemorations, such as the movie Apollo 13, were made without consulting them, leaving their lifesaving legacy largely forgotten. Half a century later, it’s time to finally tell their own story in their own words.

SETTING THE RECORD STRAIGHT

The most popular cinematic portrayal of Apollo 13 only shows a single Grumman representative briefly making an unprepossessing appearance. The following exchange (mis)portrays him as follows:

Grumman Rep: “Gene, I want you to understand we’ve never tried this before….”

Gene Kranz: “Look, it will ignite, will it not?”

Grumman Rep: “I just want you to know the engine’s never been tried like this. That’s all I’m trying to tell you.”

Gene Kranz: “Look, I know what you’re trying to do. I guarantee you, I won’t hold you personally responsible. If it lights, it lights. Let Lovell do the rest.”

Always gracious and attention-avoiding himself, Gavin nevertheless regretted that nobody had consulted Grumman in making the film, because he believed it did not properly credit his colleagues for how they had helped to save the day. He personally considered the cameo appearance of the lead Grumman representative (himself, in real life) an unfair portrayal.

I know all this because he is my grandfather, with whom I watched Apollo 13 at Tower Theaters in South Hadley, Massachusetts, upon its release in 1995. Over the years, we spent countless hours discussing this and many other aspects of the LM program that he led with great enthusiasm from Grumman’s repeatedly bidding for and finally winning the NASA contract as an unlikely underdog in 1962 to its successful conclusion with the rest of Apollo a decade later.

While I cannot and do not claim objectivity, I do hope to offer some otherwise unavailable personal insights, together with some of the heavily-footnoted research that I have pursued with a personal passion for over two decades.

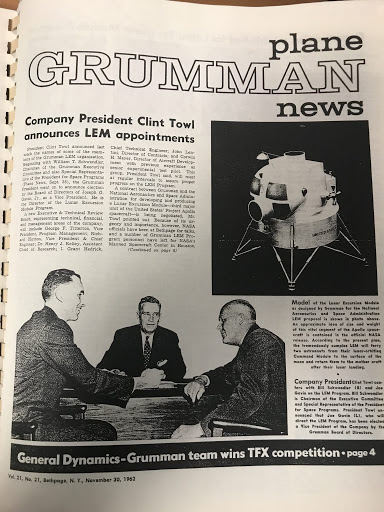

In 1962, Joe Gavin was formally named Lunar Module Program Director, and elected a Vice President of Grumman by its Board of Directors. (“Company President Clint Towl Announces LEM Appointments,” Grumman Plane News 31.21, November 30, 1962, 1.)

PRESCIENT PREPARATIONS

In reality, true to its conservative design philosophy, the Grumman Aerospace Corporation had added extra capacity and resources to power the LM as a lifeboat and tugboat of last resort. The LM’s linchpin role was anticipated overall, unanticipated in some specifics, and enabled throughout by systematic preparations.[1] While not primarily intended to provide supplemental propulsion, electricity, and oxygen in the event of a Service Module fuel tank explosion—as happened during the Apollo 13 mission—the LM was designed with considerable reserves. Indeed, five years previously, Gavin concluded in his article reviewing LM design development that “Without the necessity of starting over ‘from scratch,’ [the LM] appears adaptable to other lunar missions such as the logistics ‘truck’ as well as to Earth orbital missions which capitalize on its propulsive capacity to provide maneuverability or which make use of its compatibility with the Command Module.”[2]

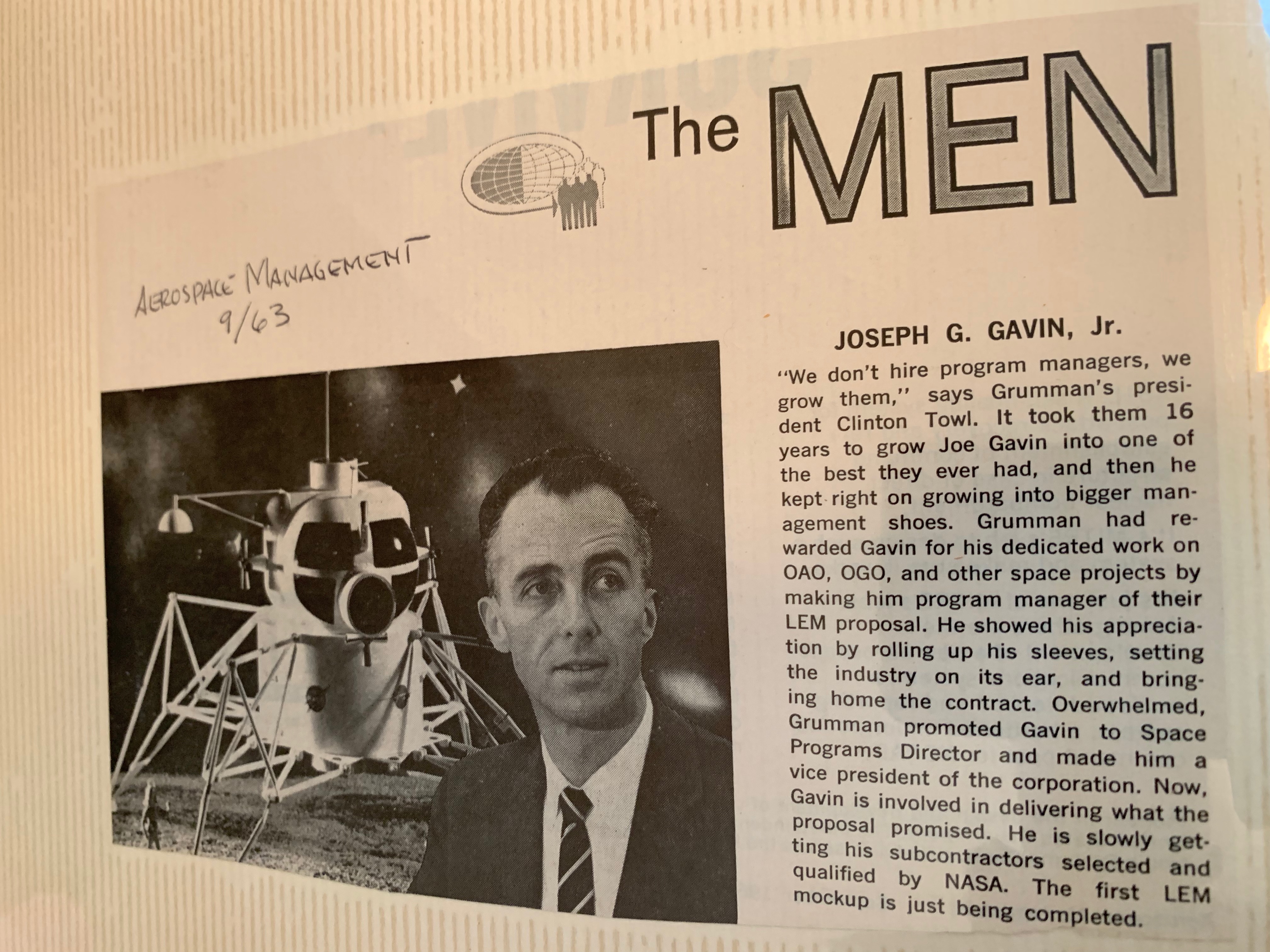

An update regarding Joe Gavin’s responsibilities as Lunar Module Program Manager from September 1963, just eight months after Grumman signed a contract with NASA. (“The Men: Joseph G. Gavin, Jr,” Aerospace Management (September 1963).)

Back in fall 1963, Apollo Command Module (CM), Service Module (SM), and Saturn V rocket second-stage contractor North American Aviation invited Grumman and Charles Stark Draper’s Instrumentation Lab at MIT, which NASA had contracted to develop the Apollo Guidance Computer (AGC), into a joint task force. Dubbed “Project Christmas Present” for the timing of its plan submission, the effort ensured badly-needed comprehensive schedule integration. As part of this effort, Grumman hosted and led mission planning, including an MIT Draper Lab contingent onsite. One outgrowth was the Apollo Mission Planning Task Force (AMPTF) in January 1964, which anticipated and addressed manifold contingencies—including the one that would save the day during Apollo 13. NASA had initiated AMPTF “to examine the various phases of the mission and look for ways to make them safer.”[3] “One major result” had been “the identification of the ‘LM Lifeboat’ mission,” which triggered prescient increases in tank size for consumables, although that role “had never been rehearsed by either the ground or flight crews or written into specific operational procedures.”[4]

“While postulating the effect of various CSM [Command-and-Service Module] failures on the outbound leg of the mission, the planners realized that a number of them could be countered by using the LM as a lifeboat and utilizing its propulsion, guidance and control, life support, and other systems to return the crew to the vicinity of the Earth’s atmosphere for re-entry in the CSM,” Tom Kelly, the LM Chief Design Engineer for the program’s first seven years,[5] later recounted. “To provide this rescue capability, some of the LM consumables, such as oxygen, water, and electrical power, would have to be increased by 10 to 15 percent above that needed to perform the basic mission. Because LM then existed only on paper, we decided to make the tanks that much larger. At a later date it could be decided whether to actually load the consumables into them. Six years after it first appeared in the AMPTF’s reports, this vital crew rescue mode was dramatically utilized on Apollo 13.”

Driven in part by specific prompting from Director of Flight Operations at NASA’s Manned Spacecraft Center in Houston, Howard “Bill” Tindall, Jr., who was charged with riding herd over Apollo software, Draper’s Lab presciently developed and loaded software that would enable the LM autopilot “to push the heavy Command and Service Modules through the limber docking joint.” Grumman and Draper’s Lab subsequently collaborated with great effectiveness in supporting Apollo flight operations, with saving Apollo 13 a shared finest hour. Whereas Grumman had added additional consumables to power the LM to as a lifeboat and tugboat of last resort, Draper’s Lab had coded and uploaded software to make sure the pushing interface remained intact. “No one had ever tested the docking collar between the LM and CM/SM on being able to survive the LM pushing the much heavier CM/SM combination. Someone, thankfully, had asked ‘What if we had to do that’ and software and been written and installed in the AGC.”[6]

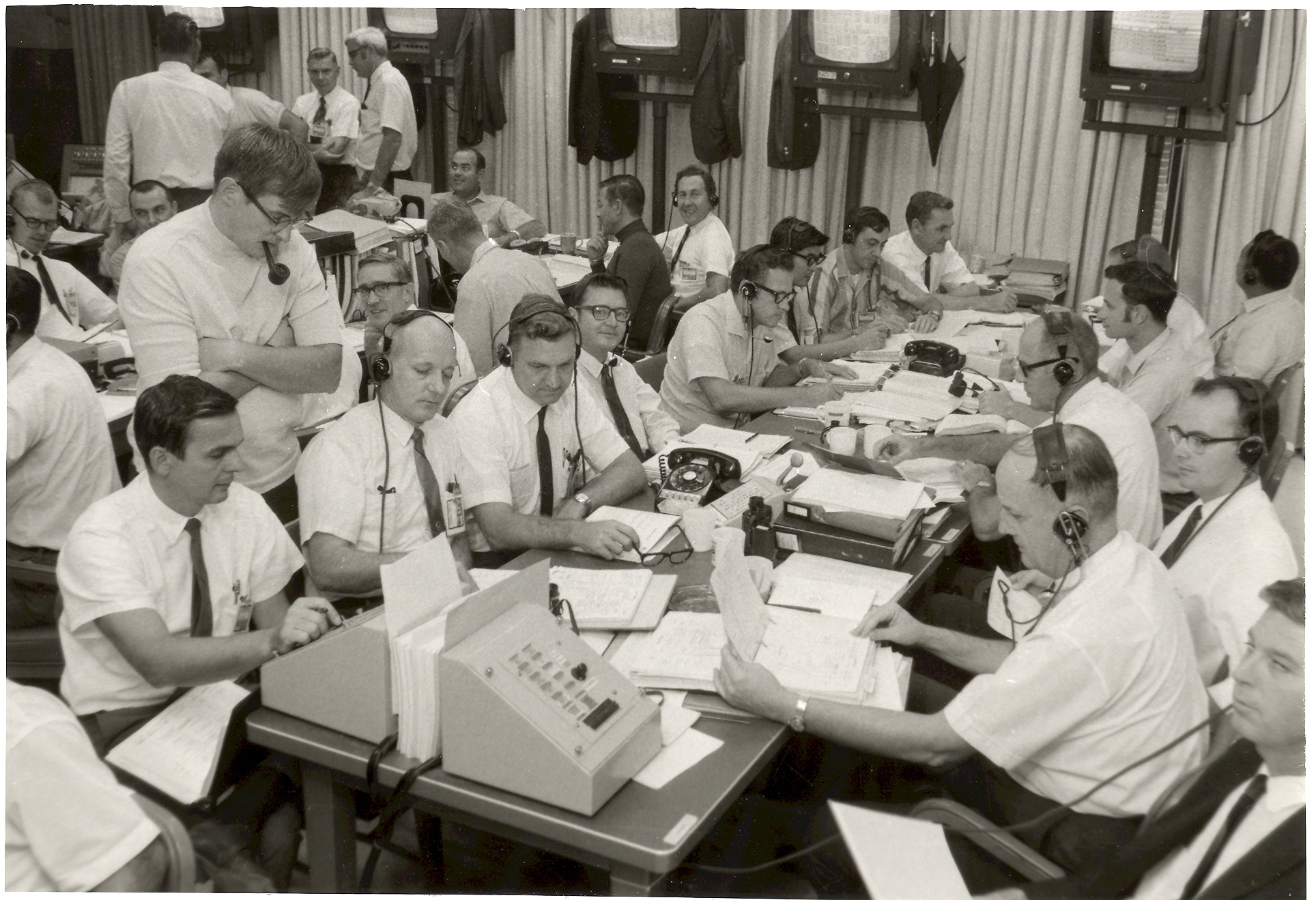

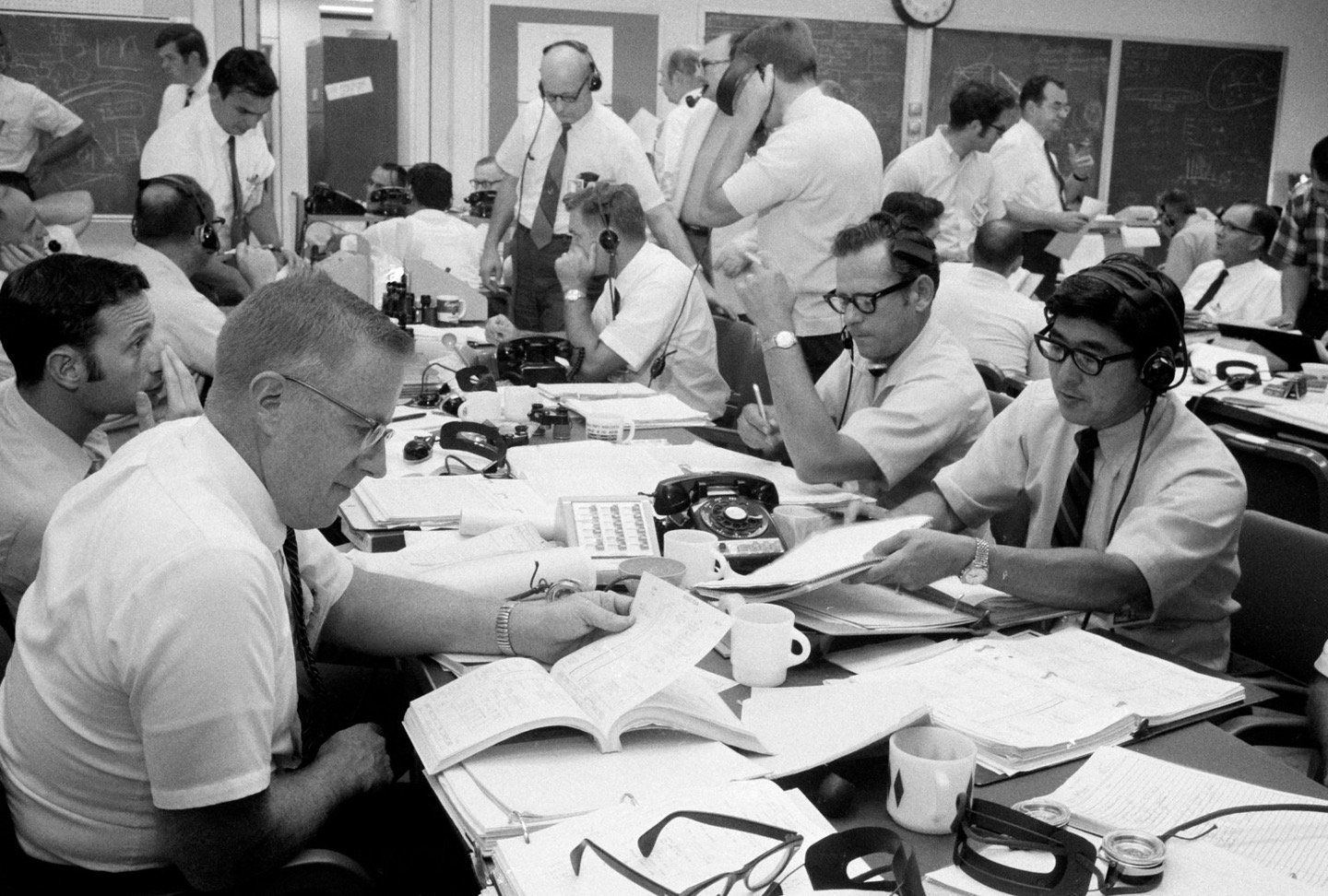

Tom Kelly (foreground) in NASA’s Spacecraft Analysis Room (SPAN) in Houston during the Apollo 11 mission. SPAN was the Apollo Spacecraft Program Office (ASPO) Manager’s official interface with the Flight Operations Directorate (FOD) and the Science & Applications Directorate (S&AD).

Grumman’s foresight exceeded that of NASA, whose otherwise extremely detailed contractual scenarios never envisioned a LM rescue mission. The company would earn no incentive rewards for saving the day.[7]

SOLVING THE PROBLEM FROM HOUSTON… AND BETHPAGE

Prior to the in-flight explosion that changed everything, Gavin had led the normal process as he did for every LM mission:

- First, a major review at Grumman’s headquarters in Bethpage, New York, before the machine was shipped to the Cape Kennedy, Florida launch site.

- Second, “almost disassembling” and checking out the vehicle at the Cape.

- Third, a three-day-prior meeting where “all principals from companies were subject to a checkout list: ‘are you ready to go’?”[8]

- Fourth, staying at the Cape from launch until the spacecraft was safely in orbit, before flying to Houston to support the mission—normally busy but routine.[9]

For example, at the three-days-prior meeting for Apollo 11 in July 1969, Gavin explained, “My job was to say the [LM] was ready. I said it was. Then, the night before the launch, there were some questions about the loading of a critical helium tank on the [LM]. I stayed at [Cape Kennedy] until about 9 o’clock to review and approve the procedures being used. Then I went back to my motel to catch a few hours’ sleep, but was back at the Cape by 1 a.m.”[10] Gavin was typically on post during missions. Always busy in the instrument room, he never witnessed a launch first-hand. Kelly recalls that Gavin “was liable to be [in the VIP viewing area] at any hour.”[11]

On April 13, 1970, two days after LM-7 was launched as part of the Apollo 13 mission spacecraft, Gavin and several colleagues were concluding a long day in Houston at the Manned Space Center’s Mission Evaluation Room (MER; the engineering support center adjoining Mission Control) with dinner and rest at their motel. It was already 10:30 p.m.—typical of the challenging hours then. “We were just about to order when the motel manager leaned over my shoulder,” Gavin recalled. “He said he’d heard there was a problem at Mission Control and he thought we might like to get over there. That did it for dinner.”

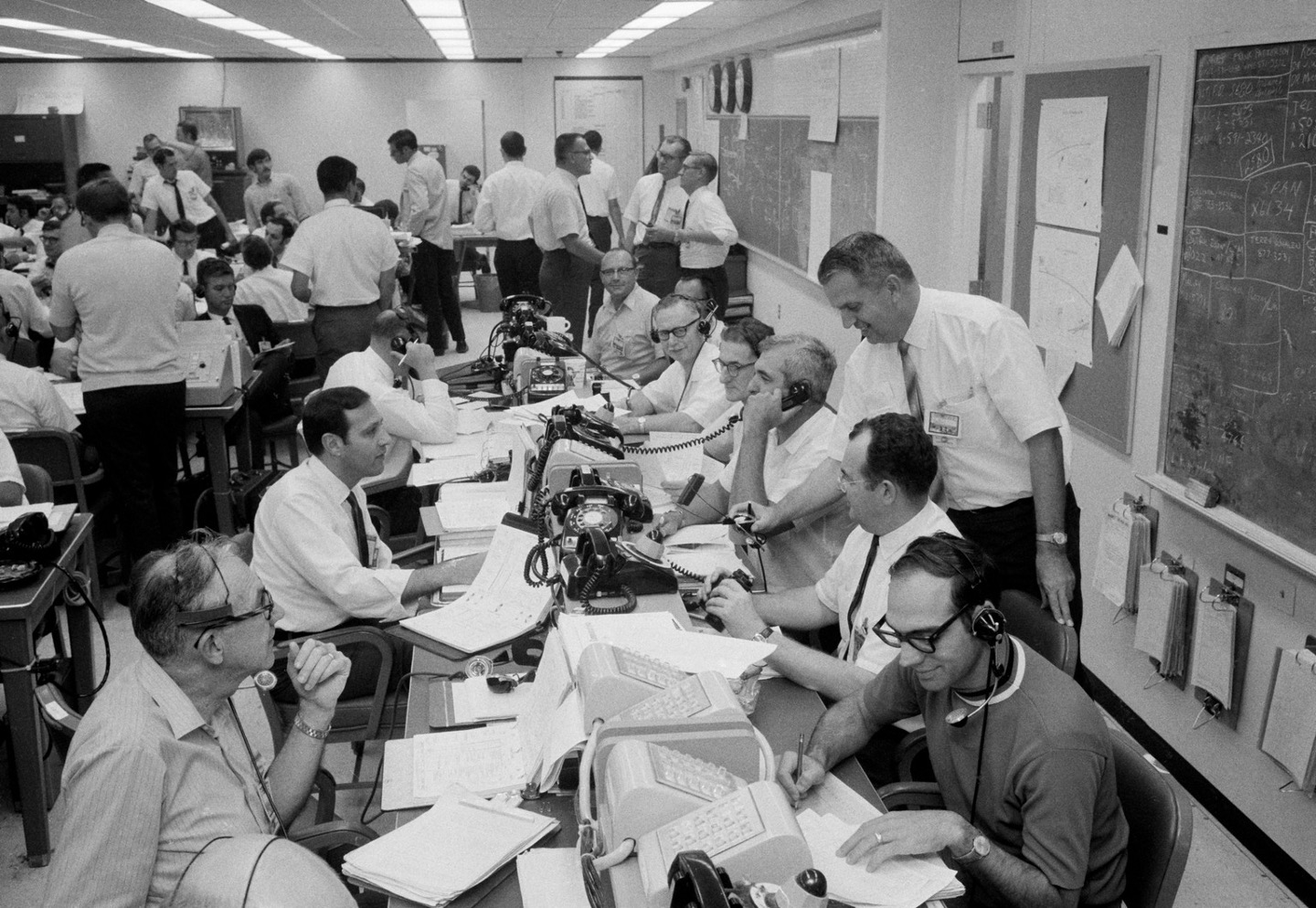

The Mission Evaluation Room during Apollo 11. Individuals pictured include John Vineze, PE7, LM Project Engineer in ASPO (Apollo Spacecraft Program Office) LM Project Engineering Division (PED); Barry Trout, EP5, “Mr. Battery” (Command & Service Module/CSM & LM) specialist in Propulsion and Power Division; Hugh Davis, PE6, LM Project Engineer, ASPO LM PED; Owen Morris, Project Engineering Chief, LM PED; Arturo Campos, EE4, LM Electrical Power Distribution SSM, Instrumentation & Electronic Systems Division (IESD); and an unnamed LM Electrical Power System Supervisor and LM Engineer from Grumman Headquarters. (NASA photo S-69-52725 courtesy of Gary Johnson, CSM Electrical Power Distribution and Sequencing, IESD. He is seated on the far left at table in foreground.)

Minutes before, at 10:08 p.m., Apollo 13 astronauts James A. Lovell, Jr., John L. Swigert, Jr., and Fred W. Haise, Jr. had heard a “pretty large bang.” Twenty-seven-year-old engineer Jerry Woodfill, whom Gavin and his colleagues would soon rejoin, witnessed the critical moment from the MER: “I looked at the console because it flickered a few times and then I saw a master alarm come on. Initially I thought something was wrong with the alarm system or the instrumentation, but then I heard Jack Swigert in my headset: ‘Houston, we’ve had a problem,’ and then a few moments later, Jim Lovell said the same thing.’”

Back at the MER, Gavin recalled, “They knew generally what had happened but they hadn’t yet been able to figure out the exact cause or the probable chain of consequences. I started by feeling, ‘It can’t be this bad’ and then went through a period of progressive disbelief as the reports came in through telemetry and spacecraft communications and we began to appreciate the full extent of the disaster. Finally it became clear that the mission had to be aborted and our Lunar Module was the only hope for the astronauts’ survival.”[12]

The Mission Evaluation Room during Apollo 11. (Courtesy of Gary Johnson.)

Gavin summarized in his dayplanner: “mid-evening CSM power failure—lunar landing aborted—desperate effort to do return mission on LM—” “I think all of us had a sense of tension in those hours that we’ve not felt before or since,” Gavin recounted.[13] Nevertheless, “The extensive preparation and analysis that’s gone on tend to make the reaction to an emergency a controlled one—no lack of emotion—but you start thinking what are the alternatives, the possibilities, the priorities.”[14]

“When the explosion of the SM oxygen tank occurred,” electrical engineer Gary Johnson later recalled, “I was in the MER and did not leave until the next morning. By then the CSM was completely unpowered and the main activity was with the engineers supporting the active LM systems.” He elaborated: “Prior to Apollo 13, I had thought about how to possibly use the CM’s battery charger to charge the LM batteries if needed. I had worked with the LM Electrical Power Subsystem Manager, Art Campos (Arturo B. Campos) and we developed a procedure using an on-board umbilical to electrically connect the battery charger output on a CM bus to the LM bus.”

The Mission Evaluation Room during Apollo 11. (Courtesy of Gary Johnson.)

Unlike its Soviet counterpart, “Apollo was a very open program.” Now it was operating under an intense national and international spotlight. Gavin led with full knowledge that he had ultimate responsibility: “One thing we did think about was: ‘Who speaks for the company if there is a catastrophe?’ And we worked that out, and I drew the short straw. My wife quizzed me about this and asked me: ‘What happens if…?’ And I said: ‘Well, we’ve thought about it. We know what has to be done. It won’t be pleasant.’ But, having been in the aircraft business for quite a number of years, we’d faced disaster before…When you deal with flying machines, when you’re defying gravity, you have to know that sometime you’re going to have a problem. I think we had grown up with that uncertainty. And I think we had a team at Grumman that thoroughly understood this.”[15]

ALL HANDS ON DECK!

Staring reality in the face, Gavin directed the Apollo Mission Support Center back in Bethpage to address the new emergency-imposed priorities: “Hoarding the consumables was first on the list. That was a fairly straightforward job of extrapolation and was already being worked on by SPAN [Spacecraft Analysis] and MER. Many of the other problems and contingencies we faced involved options which demanded considerable study and, sometimes, some trial runs on a simulator. So we had to get backup crews in the two LM test modules, one in Houston and one at Bethpage, so that we could run through the simulations of suggested procedures. Then we had to start working on problems like whether it was better to jettison the damaged Service Module or to keep it as part of the package, how the LM descent engine would perform in pushing that three-module configuration, and whether it would be wise to discard the descent section of the LM and use the ascent engine as the emergency power. They were all questions which had never been asked or answered before.”[16]

It was truly an all-hands-on-deck time for Grumman. By midnight phone call, Gavin recalled Kelly and fellow LM engineer Howard Wright from year-long Boston-based industrial management courses. They boarded a 2 a.m. chartered flight for Grumman’s Airport in Bethpage.[17] As he rushed into Grumman’s Apollo Mission Support Center at 3 a.m., Kelly saw a “flood tide” of engineers entering the building, assembling of their own accord to serve as needed.[18]

Meanwhile, in Houston, Gavin was appointed to NASA’s Mission Review Council.[19] Maintaining his post atop Grumman’s multiple layers of technical support,[20] throughout “the tensest episode in my career,” Gavin estimates that he only “got two hours of sleep in that whole [four-day] mission.”[21]

Gavin’s leadership was particularly important in determining the sequence in which systems could be shut off to save electricity without compromising their ability to be restarted when needed. Gavin’s frontline VIP room was connected by “an open line” to a nearby building, itself connected by another “open line” to Kelly and his 200-plus colleagues back in Bethpage.[22] This way, “you could get an answer on almost everything in 1-2 minutes.” Initial worries about insufficient oxygen gave way to intangible worries about “the real problem: times that just had to go by with nothing expected to happen, where you hoped that nothing would happen.”[23]

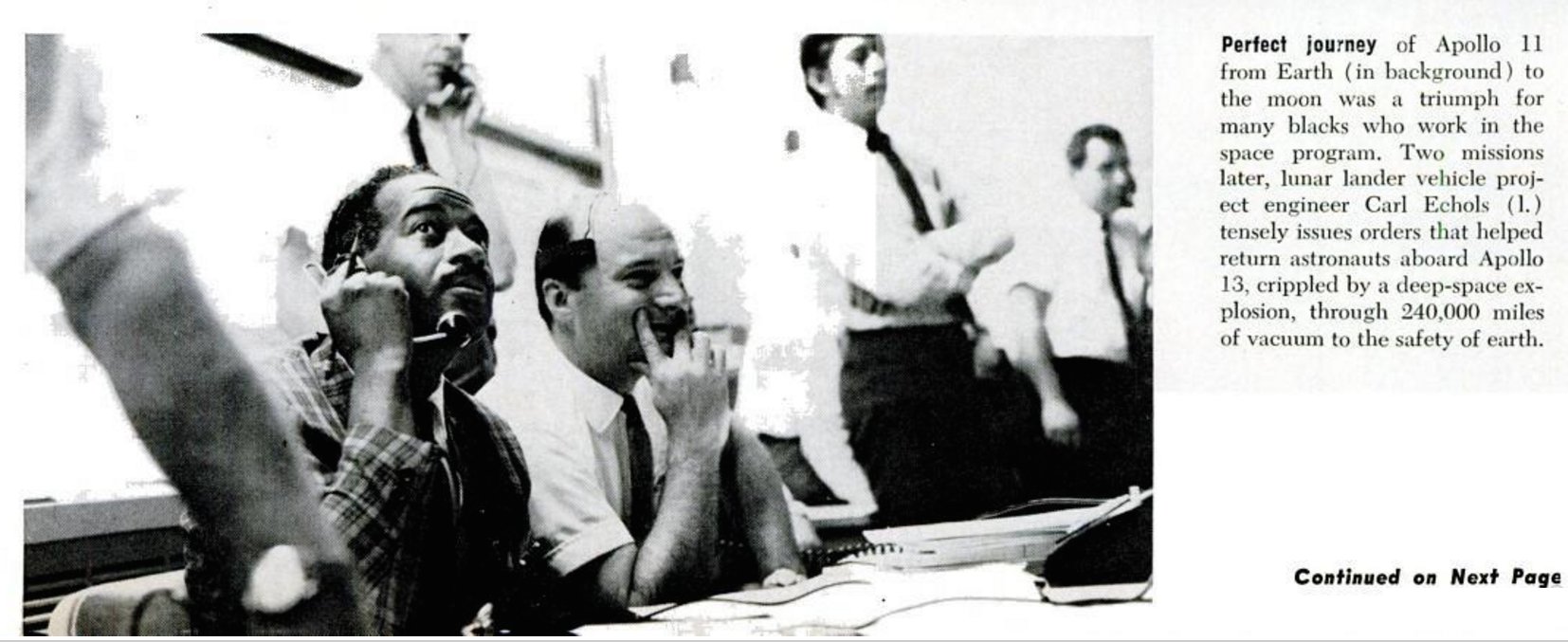

Grumman LM Project Engineer Carl Echols (left) and colleagues provided critical real-time troubleshooting and technical support throughout the Apollo 13 rescue.

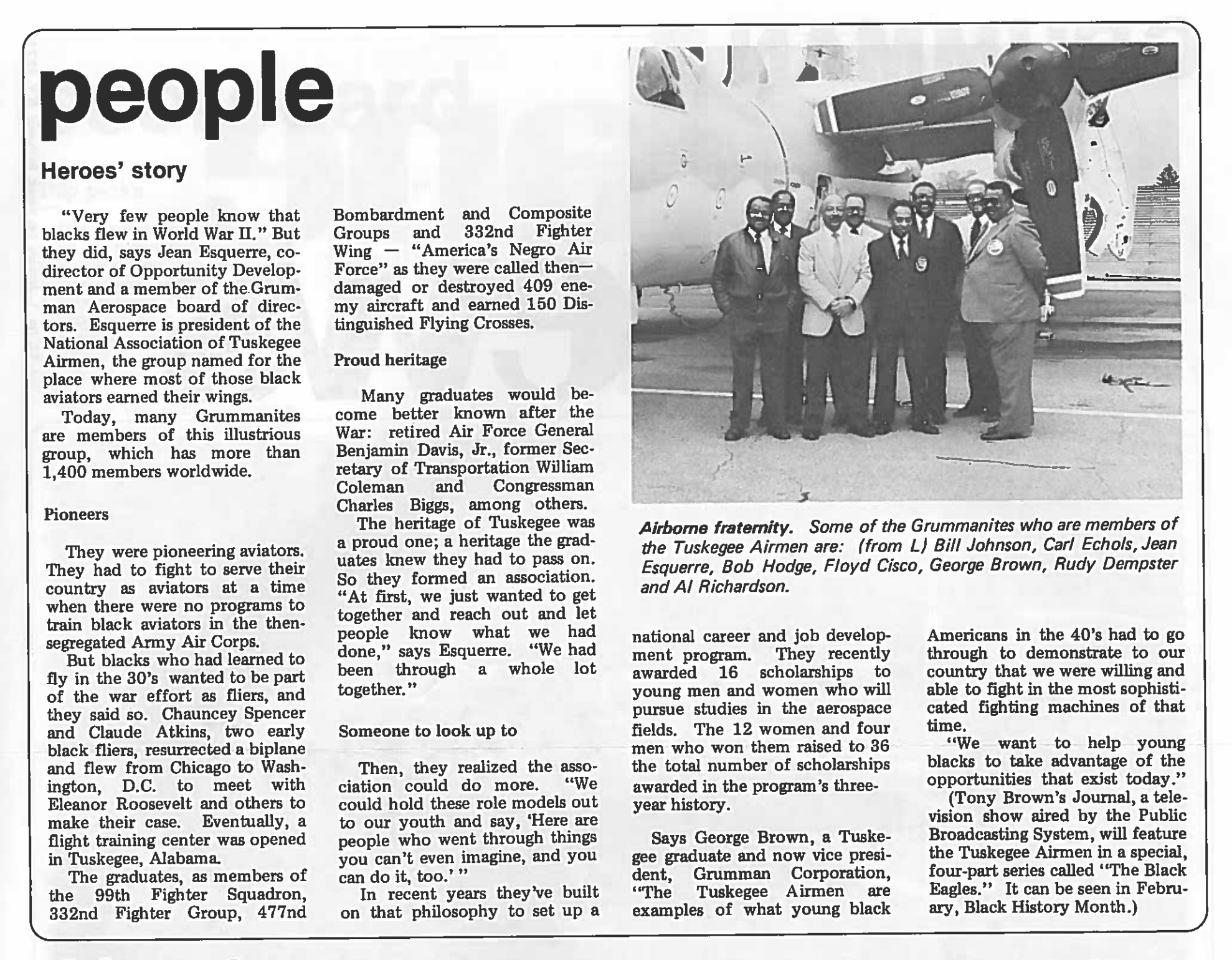

Echols was one of at least eight Tuskegee Airmen who worked for Grumman during the Apollo era. (“People: Heroes’ Story,” Grumman Plane News 41.1, January 14, 1983, 2.)

SAFE SPLASHDOWN!

“Successful splashdown—all safe!” Gavin inscribed enthusiastically in his dayplanner on April 17. NASA administrator George Low invited him to leave his post against the glass windows surrounding Mission Control to enter the main floor. The room “just burst into cheering…the atmosphere was…so buoyant….”[24] “There was a sense of relief—you could feel it.”[25] The front page of The Washington Post shows Gavin watching the astronauts’ recovery with Alan Shepard, the first American in space and subsequent Apollo 14 commander. Shepard clenches a cigar and claps, Gavin smiles.[26] Watching the movie Apollo 13 in retirement, Gavin observed that it depicted neither the small American flags that people waved in celebration nor the cigars of which he declined to partake.

Joe Gavin, standing behind astronaut Alan Shepard, watches Apollo 13’s splashdown from Mission Control. Originally slated to command Apollo 13, Shepard would instead command Apollo 14 and pilot its LM Antares to a near-perfect landing. (“Astronauts Come Home Safely,” Washington Post, April 18, 1970, 1.)

Above all, Gavin was humble and grateful: “There was a level of emotion in that group—you could cut it with a knife, because the odds of it being a successful return were pretty small. In fact, if the accident hadn’t occurred at the right point, the options to go around the moon and return wouldn’t have worked. A lot of us got pretty exhausted, but it was a good feeling to get [the astronauts] back on the carrier.”[27]

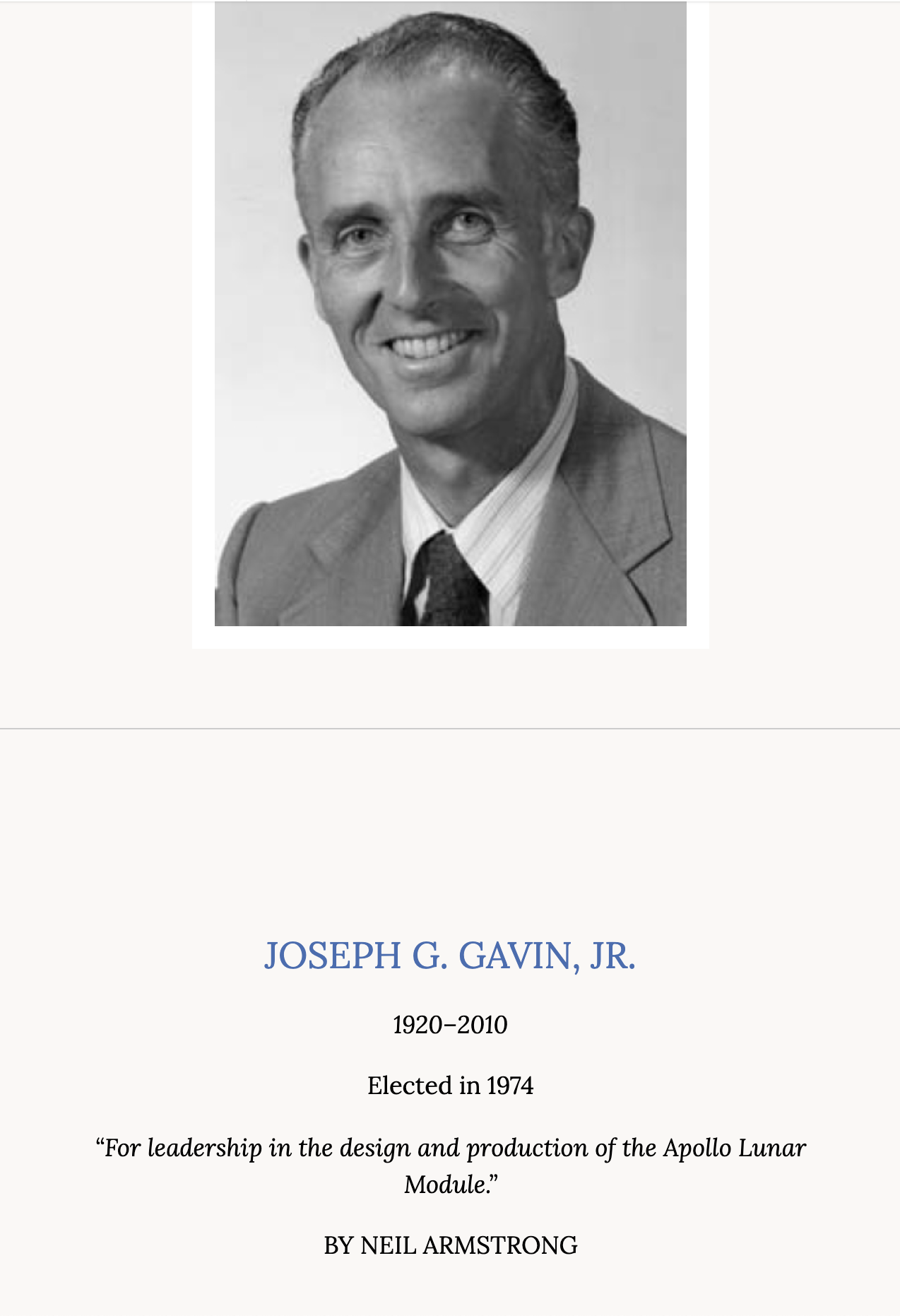

For his contribution, NASA awarded Gavin its Distinguished Public Service Medal in 1971 “as the leader and representative of the lunar module team…in recognition of the team’s outstanding skill which made possible the successful use of the lunar module as a rescue vehicle for the safe return…of the Apollo 13 crew.”[28] This followed his 1969 NASA Public Service Award for contributions to Apollo 11.[29] In 1972, the American Astronautical Society accorded him its Space Flight Award on similar grounds.[30] In 1974, in the highest professional distinction an American engineer can receive,[31] and one of his proudest career accomplishments, he was elected to the National Academy of Engineering “for leadership in the design and the production of the Apollo Lunar Module.”[32] In 2007, he was inducted into the Long Island Technology Hall of Fame.[33]

In accepting recognition, Gavin always credited these technical feats to the spirited teamwork at Grumman, across the nation, and around the world.

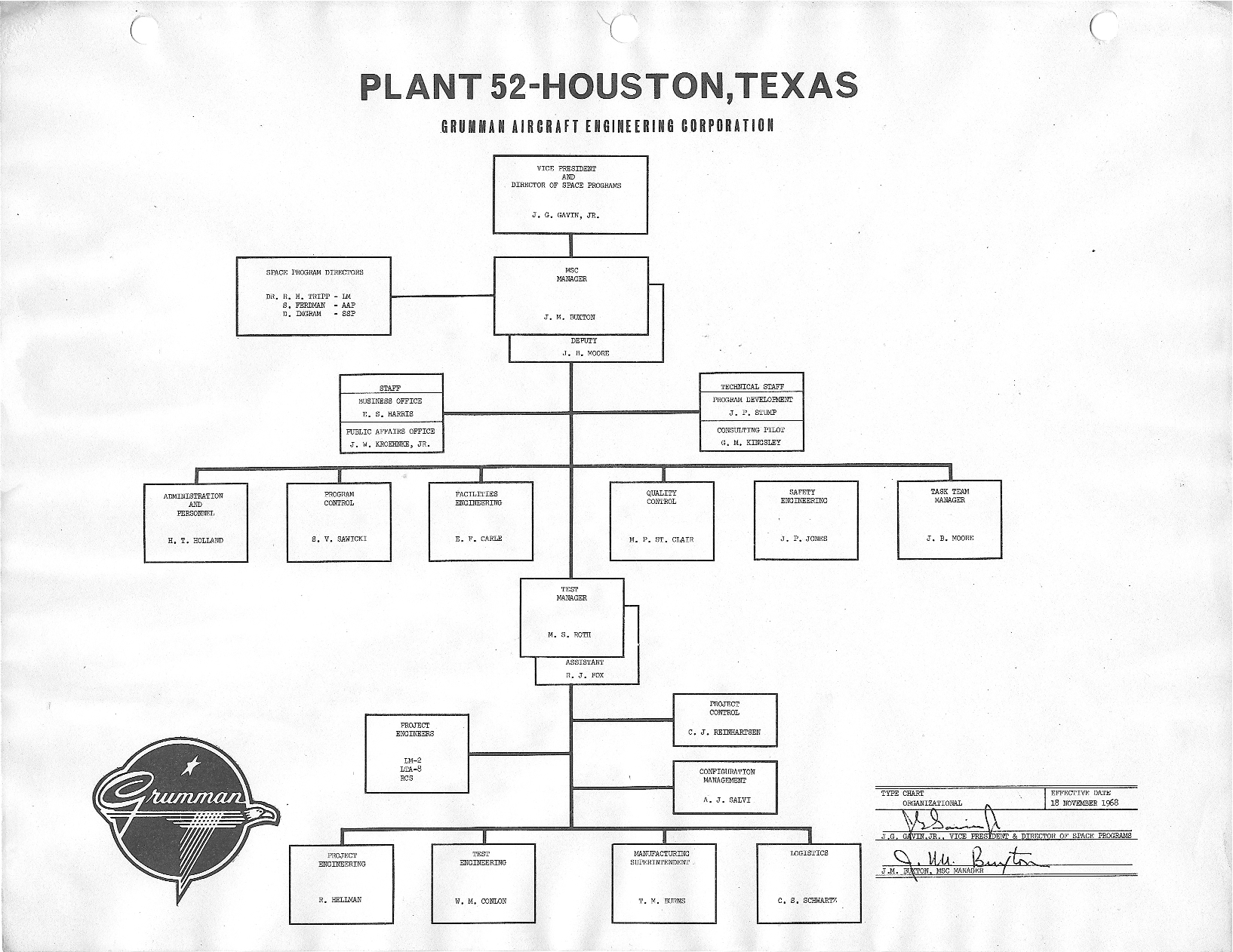

An organization chart for Grumman’s Plant 52 in Houston, TX, signed by Joe Gavin at the height of the Lunar Module Program on November 18, 1968. (Courtesy of Bill Conlon, whose father W. M. Conlon was Chief of Test Engineering.)

GRUMMAN’S COMMITMENT TO ITS PRODUCTS’ PILOTS

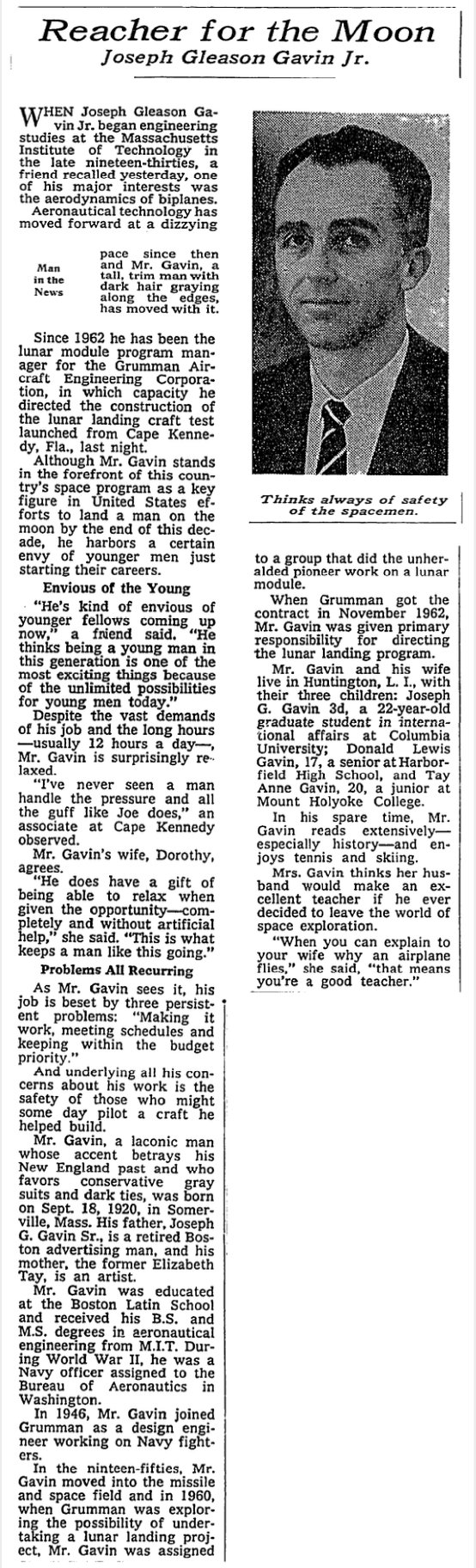

For Gavin and his team, there could be no higher priority than returning astronauts safely to Earth.[34] In Congressional testimony, Gavin highlighted “several themes which run through the programs with which we have been associated and which represent the ‘character’ of a company developed over 40 years. The first is personal identification with the crew; the continuing priority given to the safety of the men who pilot our flying machines. We can think of no better proof of the importance of this theme than the Apollo 13 [mission].”[35] When he appeared in the New York Times as “Man in the News” two years before Apollo 13, his photograph was appropriately captioned, “Thinks always of safety of the spacemen.” The article stressed that “…underlying all his concerns about his work is the safety of those who some day might pilot a craft he helped build.” [36]

Two years before Apollo 13, an in-depth interview indicates that Joe Gavin “Thinks always of safety of the spacemen” and that “underlying all his concerns…is the safety of those who some day might pilot a craft he helped build.” (“Reacher for the Moon: Joseph Gleason Gavin Jr.,” Man in the News, New York Times, January 23, 1968, 10.)

Following Apollo 13’s successful rescue, President Richard Nixon wrote to Gavin’s boss: “you and your colleagues at Grumman…who were responsible for the Aquarius Lunar Module have reason for special pride in your work. I hope you will convey my personal appreciation to all of your employees for the brilliant engineering and painstaking execution which played so major a role in the safe return of Astronauts Lovell, Haise and Swigert.”[37]

Grummanites always knew that they were building the LM for real people whose lives depended on it.[38] “The team at Grumman developed a personal relationship with every one of the astronauts in the Apollo era,” Gavin stressed. “We were building machines that our friends would operate, not some faceless individuals unknown to us.”[39] “It was not just ‘put it in a package and ship it.’”[40] While the astronauts’ personalities varied greatly, all were top-caliber professionals and “their [periodic] visits to the plant made people feel that ‘We’re not just building something for some mysterious customer; we’re building it for these people.’…that was very useful.”[41]

This embodied an ethos dating back to the philosophy of the company’s founder, World War I naval aviator Leroy Grumman, who “flew Navy” from 1918-21 and worked for a major naval airplane builder before leading several associates to establish his firm in a Long Island garage.[42] Grumman, Gavin recalled, “had one basic direction to all of us… ‘You bring the pilot back one way or another.’” Gavin shared Leroy Grumman’s core vision. Piloting was a path not taken for Gavin, but nevertheless informed his work on all the flying machines to which he contributed, including the LM. In 1946, at the end of his four years’ service in the U.S. Naval Reserve—as an engineering officer with the rank of Lieutenant posted at the Naval Bureau of Aeronautics’ Fighter Design Branch in Washington, DC—the Navy offered Gavin a chance to stay on and undergo flight training. He ultimately “decided I wanted to build something” instead, but brought a pilot-centered perspective to those efforts. “I think that as a designer, you have the feeling that ‘I could fly this thing,’ no question. ‘I know it so well that I could fly it,’” Gavin later recalled. “While I had the urge [to get and maintain a pilot’s license and fly], by Apollo 11 I was accustomed to saying [to the astronauts], ‘It’s ok to go fly it.’ That’s something you don’t say without thinking about it.”[43]

Gavin and his LM team always fulfilled the critical pilot-return requirement from Grumman’s founder. Kelly stressed: “Extensive analyses of potential single point failures have been conducted and, wherever technically feasible, the spacecraft has been designed so no single point failure can compromise crew safety.” Explaining the tremendous commitment and sacrifices that Grummanites made for the LM, Gavin emphasized, “There wasn’t any question in anybody’s mind that we were going to make it work, that we were not going to leave any astronauts on the moon, and that we were going to get them back safely.”[44]

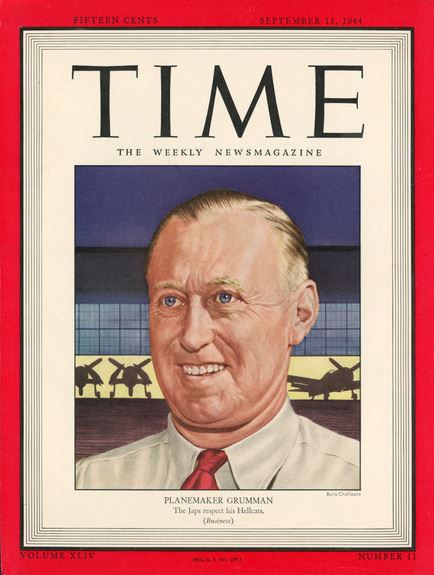

World War I naval aviator and subsequent company founder Leroy Grumman was featured on the cover of Time Magazine for his contributions to aircraft production in World War II (September 11, 1944).

Below a passage in Kelly’s book regarding NASA and Grumman’s respective responsibility for the LM’s success or failure, Gavin wrote: “I always considered Grumman to be 100% responsible.”[45] Duty was reciprocated. “NASA very wisely saw to it that one or two of the astronauts would be in the plant every month,” Gavin explained. “The astronauts ended up knowing more about the [LM] than we did. The principal example is Freddy Haise…he knew the machine better than we did.” New Yorker reporter Henry S. F. Cooper, Jr., who drove out from the city to shadow Grumman’s LM operations as an embedded observer, concluded in his resulting feature story that “Haise and other Apollo astronauts represent, even more than NASA does…‘the client.’” So intensive was his personal involvement, Haise later recalled, that when seconded to Bethpage he often slept in the LM during consecutive tests stretching as long as 27 hours. “There were times I’d be here a whole week and never get any further than Vito’s Deli, which is just across the street….”[46]

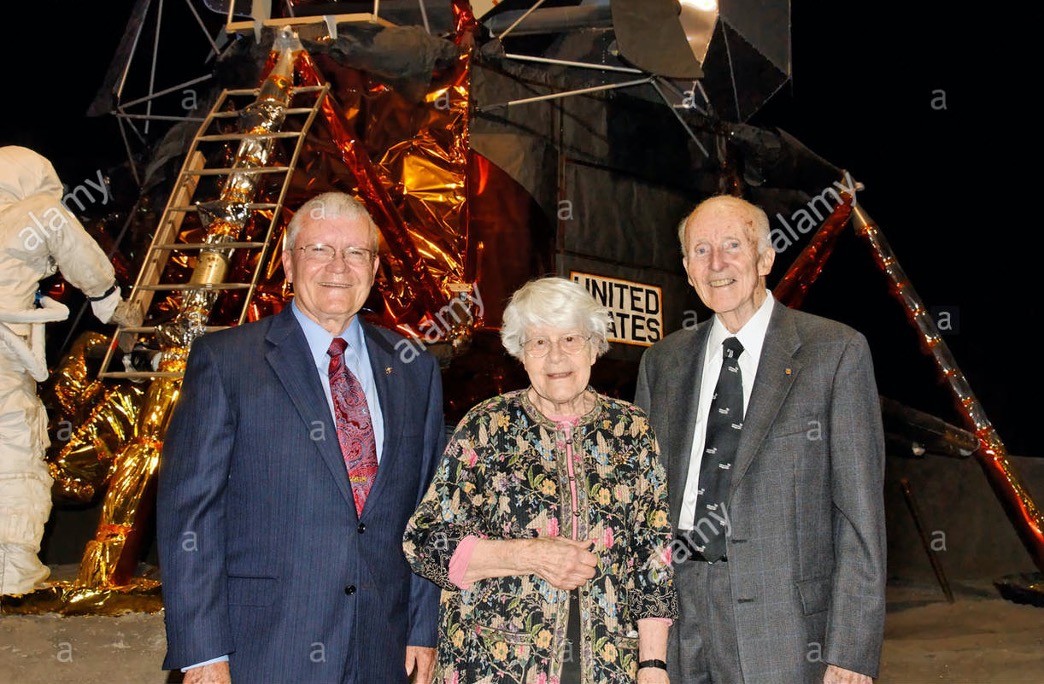

Apollo 13 LM Pilot Fred Haise (left) with Joe Gavin and his wife Dorothy in front of LM at The Cradle of Aviation Museum’s “America’s Finest Hour” celebration of the 40th Anniversary of Apollo 13. (Garden City, Long Island, NY, April 24, 2010.)

During Apollo 13, Haise’s experience and expertise would prove invaluable; he took the LM to its performance limits in unforeseen circumstances despite being severely ill. Whereas the automation-maximizing USSR lost four cosmonauts to orbital fatalities during the Apollo years, Gavin credited Apollo 13’s survival in part to the “balance between man and automatics.”[47]

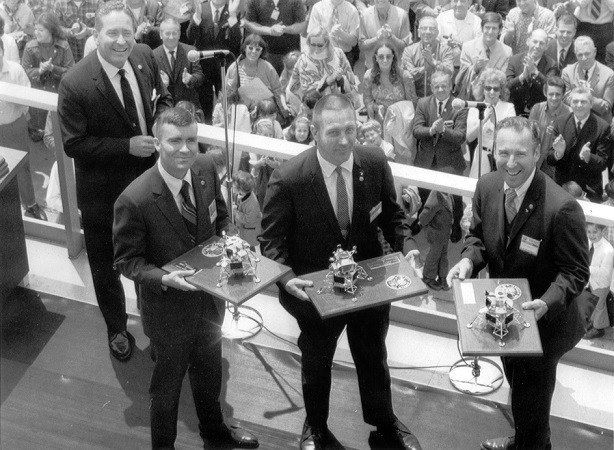

On May 5, 1970, Haise and fellow crewmembers Lovell and Swigert “came to Bethpage to thank Grumman and the LM team for saving their lives….”[48] There Haise addressed hundreds of Grummanites: “We thought, when we were out there floating [post-splashdown], ‘if we don’t do anything else, let’s get back up to Grumman and say ‘Thanks.’”[49]

Apollo 13 astronauts (from left to right: Haise, Swigert, and Lovell) visited Bethpage to thank the Grumman Team for its lifesaving Lunar Module. (Bethpage, NY, May 5, 1970.)

Reaction Control System Project Leader Ozzie Williams “recall[ed] three firm handshakes and three voices saying ‘thanks’” in his office. The astronauts indeed owed Williams and his colleagues their personal appreciation.

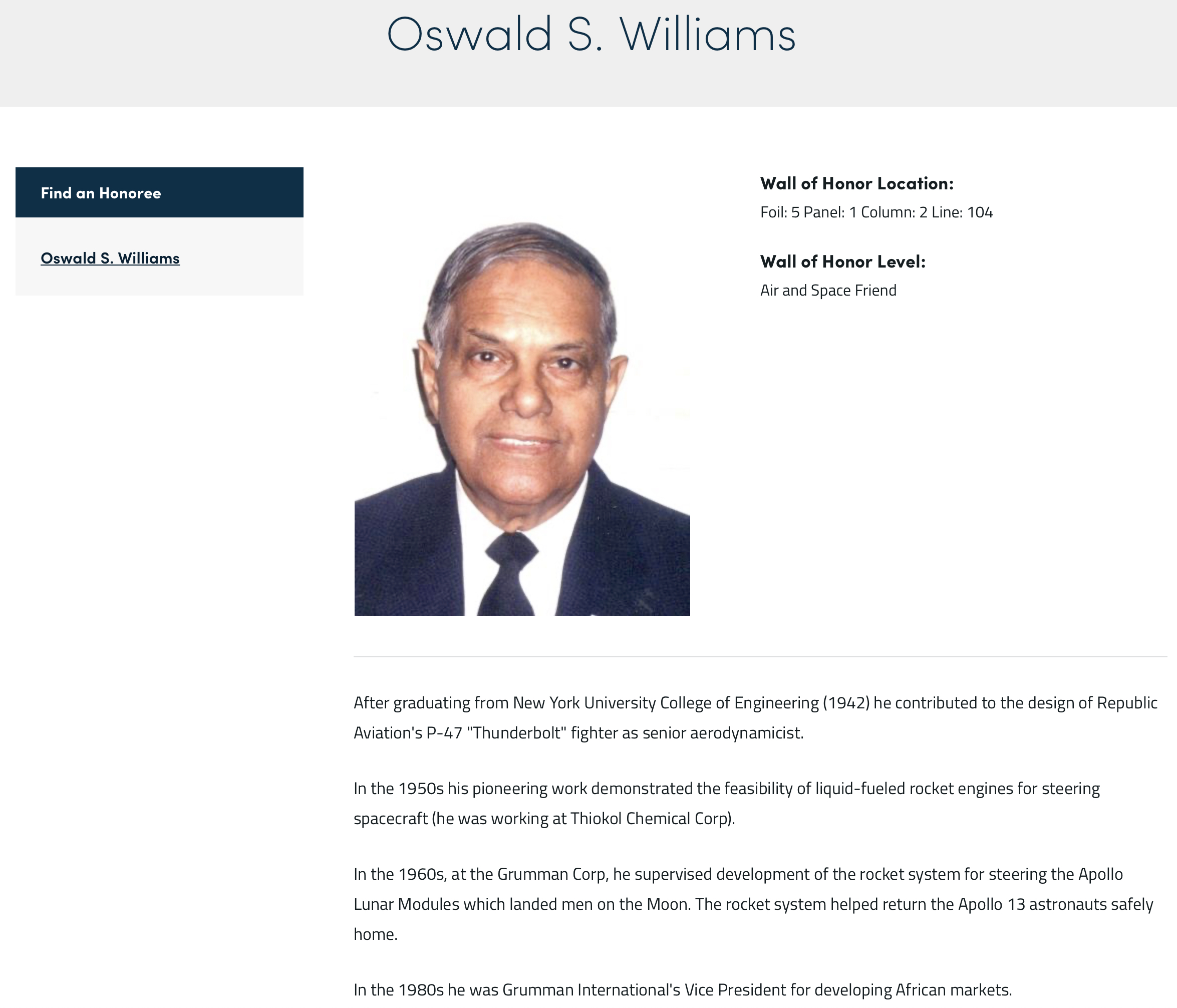

As William recalled in the September 1970 issue of Ebony magazine, “From the beginning, we designed the lunar lander [reaction] control system with 16 engines for just such an emergency as Apollo 13’s… For the lunar landing itself, we could squeak by with only eight engines. We always felt that in an emergency there were various uses for my engines, but we were hoping it wouldn’t happen.” In true Grumman tradition, Williams explained, his engines “were ‘over designed,’ that is, built to handle much more than they [normally] needed to. Their extra capacity enabled the astronauts to reenter the Earth’s atmosphere at a safe angle.” For such contributions, he is featured on the National Air & Space Museum’s Wall of Honor.

Oswald S. “Ozzie” Williams is recognized on the National Air & Space Museum’s Wall of Honor, particularly for his leadership in developing the Reaction Control System that helped save Apollo 13.

Deeply touched for the trio’s thanks for “having designed ‘the little engines that could,’” he later joked, “‘I haven’t washed that hand for thirty years.’” Williams concluded: “To paraphrase Dr. Martin Luther King’s famous words, all of us Grummanites had ‘been to the mountaintop’ that day.”[50]

Ozzie Williams overcame tremendous personal adversity to make a leading contribution to the rescue of Apollo 13. He later became a Vice President of Grumman.

GAVIN’S LEGACY: “WOULD I ASK MY BEST FRIEND TO GO AS A PILOT?”

Gavin enjoyed an extraordinary engineering-executive career in an extraordinary age for American aerospace accomplishments. “Joe Gavin has provided leadership for some of the greatest achievements of Grumman’s post-war history,” Chairman John Bierwirth concluded upon Gavin’s retirement in 1985. “No other company in the world can claim for its legacy the first landing on the moon and the lifeboat mission that saved Fred Haise and his crewmates. Since 1976, Joe has been our president and chief operating officer through a time of change and challenge that has seen our sales and equity double, our earnings increase four times, and…in which Grumman has become recognized around the world as the premier producer of flying electronic systems.”[51] For Gavin and Grumman, however, it was during the heady LM years (1962-72) that their space-related efforts reached their apogee.

Through these efforts, Gavin enjoyed fascinating personal experiences.[52] He met President Lyndon Johnson at the White House, attended the black tie event President Richard Nixon hosted honoring the Apollo 11 astronauts, and briefed Senators and Congressmen.[53] Most meaningful to him: “I met Orville Wright before he died…showed Charles Lindbergh the Lunar Module under construction;[54] [and] survived the anxious hours of Apollo 13.”[55]

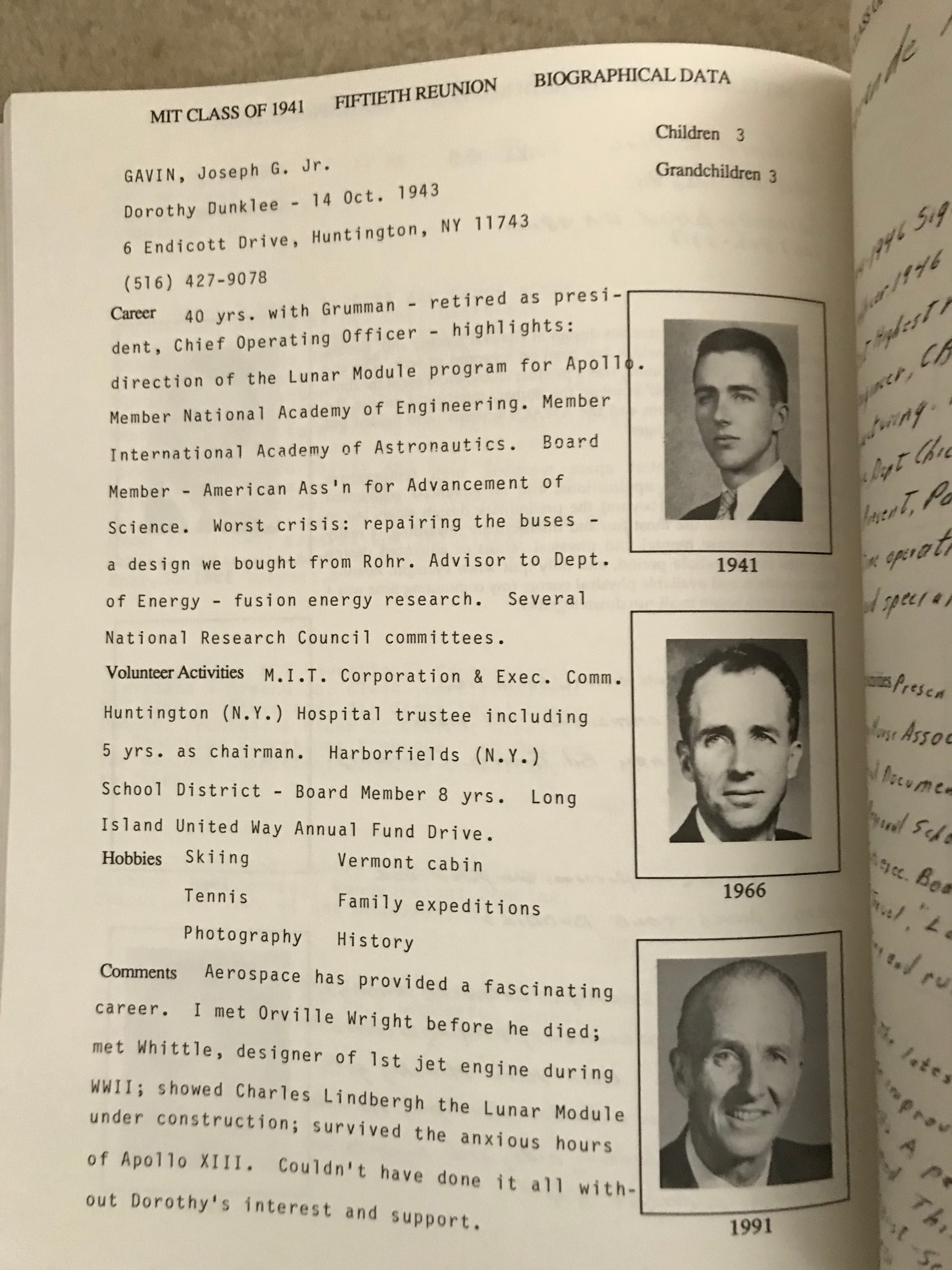

With characteristic brevity, Joe Gavin summarized his life and career half a century after graduating from MIT. “Highlights: direction of the Lunar Module program for Apollo.” (“Gavin, Joseph G. Jr.,” 50th Reunion Yearbook (Cambridge, MA: MIT Class of 1941, June 3-8, 1991).)

On June 11, 2010, less than six months before his death, Gavin shared the Cabot Award for his lifetime legacy. Recipients are “individuals or teams who have made unique, significant, and unparalleled contributions to advance and foster aviation or space flight.”[56] It was presented by the Aero Club of New England, America’s first aeronautical club.[57] Gavin discussed discoveries and protocols that ensured LM reliability, recounted the extreme sleep deprivation he had endured in helping to save Apollo 13, and expressed gratitude that he would never have to repeat the experience. In a fitting followup, Apollo 13 Commander Lovell would receive the same award in 2018.

Asked to define his profession, Gavin opined, “I think aerospace engineering is a little bit different. The margins are less, and you’re defying gravity every day. The results, if you fail, are quite notable. If you look at the margins of safety in a bridge or an airplane, it’s really a different game. Being an aeronautical engineer myself, [I can attest that] we live more dangerously. And so we’re more careful.”[58] He elaborated: “if you don’t do a superior job [of systems engineering], the results are catastrophic, and wind up on page one. And you really can’t afford to have that happen.”[59]

No matter how high he rose in leadership, Gavin always remained an aerospace project engineer at heart. It was in that role, most prominently in the climactic Apollo decade, that Gavin made the contributions for which history will most remember him. It is only fitting, then, that perhaps his most personally-revealing, professionally-autobiographical writing—produced when he was LM Program Director—describes this role “from a very personal point of view.” As part of a far-ranging, “immense responsibility,” Gavin held, an aerospace project engineer must answer “a few very basic questions…in almost every instance;

“If I permit the project to progress in this direction

- Would I go as a pilot?

- Would I ask my best friend to go as a pilot?[60]

- Would I invest my own money?

- Does this action really count?”

Gavin never failed to give satisfactory answers to these questions. The results live on in the first and only piloted vehicles to reach another celestial body; and in the many individuals whose lives he touched, including the families of three astronauts who never would have returned home without a conservatively-engineered lifeboat: the Grumman Lunar Module.

That extraordinary story could make a great movie someday…

Lunar Module Program Director Joe Gavin in his office with a model of the Lunar Module. (Grumman Aerospace Corporation, Bethpage, NY, January 1969.)

Gavin’s obituary observes: “A memorable feat performed by the [Lunar] Module came in April 1970, when it acted as a lifeboat after an oxygen tank exploded aboard the Apollo 13 spacecraft. … All the while, Mr. Gavin and others were at mission control in Houston helping to guide the men to safety. NASA awarded Mr. Gavin the distinguished public service model for his role in the crisis.” (Douglas Martin, “Joseph Gavin, Who Helped Put First Man on Moon, Dies at 90,” New York Times, November 7, 2010, 34.)

APPENDIX: HOW THE AEROSPACE PROJECT ENGINEER SAW HIS ROLE

Even as Gavin subsequently assumed higher management responsibilities culminating in leadership of Grumman itself, he remained an aerospace project engineer at heart. In a rare instance of personal expression on the subject, he elaborates on these points below.

Problems Facing the Aerospace Project Engineer—Industry Viewpoint

Joseph G. Gavin, Jr.

Vice President, Director LEM Program, Grumman Aircraft Engineering Corporation

Rather than pursue the problem of the aerospace project engineer at a distant philosophical level, I would like to examine them from a very personal point of view. To begin with, let’s establish a definition. The Project Engineer referred to here is the senior technical person holding line authority in a major program. Sometimes this person is called the Engineering Manager of a program. This distinction is necessary because occasionally the term ‘project engineer’ is applied to levels of engineering supervision more traditionally known as group leaders. This Project Engineer, of whom I speak, carries an immense responsibility, and must at various times display talents worthy of Albert Einstein and John Foster Dulles.

Let’s first examine his technical problems. While he cannot be expected to be expert in all disciplines, he must be reasonably at ease in considerations ranging from heat transfer to digital data handling. His comprehension level must be sufficient to earn the respect of the various specialists within his organization. Modern complex systems require difficult trade-off and integration compromises. With the support of his group leaders, the project engineer must define the proper compromises without inordinately lengthy studies. He must require from his crew adequate, useful, and convincing information; he has to resist the sometimes-easier course of asking for further investigation—beyond the level of real significance. For example, in the LEM program, we are now examining a very interesting compromise—should weight be invested in a stronger landing gear to permit rougher landings or more propellant to permit better landings? We could continue to embroider this study for months; but we won’t, we must avoid this temptation.

Another technical hurdle for the project engineer is the undefined or “floating” requirement. Designing to provide margin for such requirements requires conservative boldness—or is it bold conservatism—and strong convictions. Pursuing the example of the LEM, we are currently wrestling with the problem of what constitutes reasonably safe assumptions with regard to the lunar surface. How high a coefficient of friction might an assumed dust layer provide? A course of action will have to be taken long before all the answers are available; our solution must provide a reasonable degree of flexibility to cover the range of possibilities.

A further technical demand on our project engineer is a clear understanding of those areas within the project which press the state-of-the-art. The problem usually occurs in two steps; first to recognize these areas, and second to limit them. Our Orbiting Astronomical Observatory is an example of a program made rather difficult by the necessity of pressing the state-of-the-art in a number of areas simultaneously in order to achieve the desired results. In this case, astronomical precision has placed unusual demands on such things as star tracker gimbal angle accuracy, control of heat flux to minimize structural distortion, and data handling and storage capacity—all at unprecedented reliability levels. Again, without proper evaluation and approach, we could not have progressed from analysis to hardware.

In reviewing the project engineer’s role, it is sometimes surprising to see how much of his efforts are devoted to administrative problems. He must maintain a delicate balance of emphasis between project and discipline—his specialists must be clearly project oriented, yet they must benefit from their ties with colleagues on other projects. The project engineer must resist the tendency for the myriad of insignificant, and therefore easier, administrative demands to dilute his attention to the significant and frequently thorny technical questions. At the same time, he must exercise judgment with respect to the delegation of both technical and administrative responsibilities—he must resist the temptation to carry out each study himself; he cannot funnel every detail through his office. By these last comments, I do not mean to imply that his administrative role is less important than his technical role. He must take a leading part in cost and schedule estimates—otherwise neither he nor his subordinates will live up to these seriously. He must demonstrate administrative as well as technical control to limit overelaboration, to resolve group interfaces, and to ensure coordinated milestone accomplishment.

While engineering education seldom stresses this point, a surprising proportion of the project engineer’s trials and tribulations are in reality people problems. He must be able to approach each subordinate in a manner which will result in optimum performance. He must be able to apply the appropriate “filter” to each subordinate’s comments so that the information is “normalized.” He must exhibit leadership, must be able to inspire others to lead, and must be able to evaluate performance objectively. He must be able to communicate effectively within his engineering project, within the program organization, with representatives of the procuring agency, and with sub-contractors. One of his toughest tasks is to recognize and acknowledge those occasions when he is wrong.

In the case of manned vehicles, he is also confronted with the necessity of working with, understanding, and communicating with pilots or astronauts, as the case may be. Success for the project depends on the development of mutual respect.

Having progressed from technical problems to a discussion of human relations, I may as well go all the way and reduce the project engineer’s considerations to a few very basic questions which he must answer in almost every instance;

“If I permit the project to progress in this direction

- Would I go as a pilot?

- Would I ask my best friend to go as a pilot?

- Would I invest my own money?

- Does this action really count?”

The project engineer can make use of the most refined methods—systems studies, multi-variable mathematical analysis, elaborate simulations and tests—but, in the end, he has to satisfy these questions.

In principle, everything I have said was just as true 10 to 15 years ago as it is today. What then are the differences which make the job of today’s project engineer more difficult? Here are a few:

- Today’s major program is larger, represents a greater technical step ahead, and is one among a smaller number of national programs. This makes every decision more significant in terms of either money or effort. Each decision requires greater justification and more careful analysis of its implications.

- The quest for performance—of all kinds—inspired by mission requirements and industrial competitiveness has increased the level of effort as well as the caliber of talent required to do all but the simplest engineering tasks.

- Flight testing has always been expensive and potentially dangerous. With the advent of manned space flight the magnitude of these conditions has increased drastically. More patience and ingenuity must be exercised in testing on the ground. The probability of mission success and mission safety must be explored with far greater care and understanding.

- And finally, I am convinced that, under the pressure of these more demanding programs, a better professional engineering job is being accomplished today—not easier but better.

More detailed technical study supporting the decision-making process, more detailed test programs with additional emphasis on extracting the maximum amount of information from every level of testing. Efforts such as these, and the multitude of others covering every technical—and human—aspect of the program, are the responsibility—and the salvation—of the project engineer of today’s space programs.

Four years after Apollo 13, in one of his proudest career accomplishments, Joe Gavin was elected to the National Academy of Engineering “for leadership in the design and the production of the Apollo Lunar Module.” (Neil A. Armstrong, “Joseph G. Gavin, JR. 1920-2010,” in Memorial Tributes: Volume 15 (Washington, DC: National Academies Press, 2011), 111-14.)

NOTES

[1] Key example: power. “The CSM [Command-and-Service Module]/LM electrical interface was designed so that the CSM would provide electrical power to the LM during the translunar phase of the mission. The reverse condition, LM power to the CSM, was not a design requirement and was never attempted prior to the Apollo 13 problem. The LM Descent batteries were estimated to have delivered a total 1567 amp hours out of a rated total capacity of 1600 amp hr. The batteries were unevenly discharged so that some batteries exceeded the spec requirement (i.e., one battery delivered 428 amp-hours compared to the 400 amp hr spec requirement).” “LM-7 (Apollo 13),” unidentified document examined by author.

[2] Joseph G. Gavin, Jr., “LEM Design Evolution,” Astronautics & Aeronautics (April 1965): 51. See also, “Lunar Module Derivatives for Future Space Missions,” in Richard Hoagland, Apollo Spacecraft News Reference (Bethpage, NY and Houston, TX: Grumman Aerospace Corporation and NASA Manned Spacecraft Center), LMD-1 to -13; same title, undated brochure and drawings; “Looking Past Apollo for Future Space Missions for LEM Vehicle,” Grumman Plane News, November 29, 1965, 5. Gavin mentioned the LM “truck” variant in his dayplanner on May 13, 1964; June 3, 1964; and June 12, 1964. He mentioned LM “TUG” on February 4, 1965. On April 25, 1969, he noted a “pitch on LM derivatives.” Gavin references “LM-A” on June 12, 13, 16, and 27; as well as July 7 and 8, and August 5, 1969. He mentions “LM-B” on July 8, 1969. “We at Grumman had developed a very interesting and I think reasonable practical program for expanding the exploration of the moon,” Gavin recalled, “that…involved modifications of the Lunar Module to carry different kinds of equipment, and…the development of a rover that would be pressurized so that it could be operated under shirt-sleeve conditions, with a greater range of maneuver….” Author’s interview with Gavin, Amherst, MA, December 11, 1998.

[3] Thomas J. Kelly, “A Review of the Apollo Lunar Module Program and its Lessons for Future Space Missions,” paper presented at Space Programs and Technologies Conference, Huntsville, AL, September 25-27, 1990, 4, https://arc.aiaa.org/doi/10.2514/6.1990-3617.

[4] Kelly, Moon Lander: How We Developed the Apollo Lunar Module (Washington, DC: Smithsonian Books, 2001), 226. The following claim suggests that some relevant training had occurred: “this current mission, with a loss of power in the command module, was flown many times in the simulators. When the explosion happened Monday night, the crew had started to climb into the LEM [LM] even before the flight director told them to, they were so familiar with what probably would happen.” Martin Waldron, “Flight Director Is Making the Decisions,” New York Times, April 16, 1970, 30.

[5] “Tom Kelly, the LM chief engineer, is one of the finest engineers that ever worked for me, a friend for over fifty years,” Gavin recalled. “We sent Tom to the Sloan School at MIT after Apollo 12, and I called him back, temporarily, for the Apollo 13 crisis.” Gavin, comments written in December 2001 in Kelly, Moon Lander. For Kelly’s experiences in this position, which he held from 1961-69, see Kelly, Moon Lander. On April 9, 2001, Gavin inscribed in the copy Kelly sent him: “I’ve known Tom since he first arrived at Grumman—an exceptional talent, right from the start. A fine person to work with—one of Grumman’s ‘tried and true.’” See also Gavin, with contributions by Joan Kelly, “Thomas J. Kelly, 1929-2002, Elected in 1991,” Memorial Tributes, National Academy of Engineering of the United States of America, Volume 11 (Washington, DC: National Academies Press, 2007), 179-81.

[6] For Kelly quotation, see Kelly, Moon Lander, 77. See also: “1966 March 17—Apollo Time-Critical Aborts Due to Service Propulsion System Failure Investigated,” http://www.astronautix.com/l/lmecs.html:

“John D. Hodge, Chief of MSC’s Flight Control Division, proposed that time-critical aborts in the event of a service propulsion system failure after translunar injection (TLI; i.e., insertion on a trajectory toward the moon) be investigated. Time-critical abort was defined as an abort occurring within 12 hours after TLI and requiring reentry in less than two days after the abort.

He suggested that if an SPS failed the service module be jettisoned for a time-critical abort and both LEM [LM] propulsion systems be used for earth return, reducing the total time to return by approximately 60 hours. As an example, if the time of abort was 10 hours after translunar injection, he said, this method would require about 36 hours; if the SM were retained the return time would require about 96 hours.

He added that the LEM/CM-only configuration should be studied for any constraints that would preclude initiating this kind of time-critical abort. Some of the factors to be considered should be:

- maximum time the LEM environmental control system could support two or three men on an earth return;

- maximum time the CM electrical system could support minimum power-up condition;

- time constraints on completely powering down the CM and using the LEM systems for support;

- effects on planned landing areas from an open loop reentry mode;

- stability of the LEM/CM configuration during the descent and ascent propulsion burns;

- total time to return using the descent propulsion system only or both the LEM’s descent propulsion system and ascent propulsion system; and

- communications with Manned Space Flight Network required to support this abort.”

For related background, see Kelly, Moon Lander, 73-77, 79;Charles Fishman, One Giant Leap: The Impossible Mission That Flew Us to the Moon (New York: Simon and Schuster, 2019), 135-59. On Tindall specifically, see Memorandum to PA/Manager, Apollo Spacecraft Program, from EA/Director of Engineering and Development, “LM Propulsion of the LM/CSM Configuration as an SPS Backup Technique,” EG-23-88-68-486, May 1, 1968, http://www.collectspace.com/resources/tindallgrams/1968_tindallgrams.pdf. This item references a dozen related memos. Handwritten annotations suggest significant circulation and follow-up. The following extensive-but-incomplete set of widely-acclaimed “Tindallgrams” memoranda documents key technical decisions made for all unmanned and manned flights through Apollo 13 (1966-early 1970): https://wehackthemoon.com/sites/default/files/2019-03/tindallgrams02.pdf. Quote regarding docking joint is from David G. Hoag, “The History of Apollo Onboard Guidance, Navigation, and Control,” Journal of Guidance, Control, and Dynamics 6.1 (January-February 1983): 5, https://arc.aiaa.org/doi/abs/10.2514/3.19795. Quote regarding docking collar is from George T. Schmidt, V.P. Technical Operations, Aerospace and Electronic Systems Society, Institute of Electrical & Electronics Engineers, “Inside Apollo: Heroes, Rules and Lessons Learned in the Guidance, Navigation and Control (GNC) System Development,” Sigma Xi Honor Society Public Lecture, University of New Mexico, Albuquerque, NM, September 16, 2019, 7, https://wehackthemoon.com/sites/default/files/2019-08/Inside%20Apollo%202019%20Title%20Location%20Fixed_0_0.pdf.

[7] “Slide 32—Incentive Targets,” D.F. Schlegel and D.J. Markarian, “Apollo Lunar Module Legacy,” presentation, American Institute of Aeronautics and Astronautics Meeting, Denver, CO, July 1973.

[8] Michael Dorman, “A Giant Step for LI: Grumman’s Lunar Module Ferries Astronauts on a Dangerous Mission to the Moon,” Newsday (Long Island), June 14, 1998, A16.

[9] Brian Keegan, Interview of Joseph G. Gavin, Jr., Infinite History Project, MIT, July 17, 2007, https://infinitehistory.mit.edu/video/joseph-g-gavin-jr-’41-sm-’42.

[10] Dorman, “A Giant Step for LI,” A16.

[11] Kelly, Moon Lander, 210. What distinguished Apollo 13 was the lack of occasional downtime to sleep.

[12] Richard Thruelsen, The Grumman Story (New York: Prager, 1976), 13.

[13] “Part 4: The Lunar Module,” Moon Machines, Science Channel HD documentary miniseries, June 2008, https://www.youtube.com/watch?v=f2Tc8z2xO74.

[14] Bruce Lambert Jr., “Space Medal Winner Credits Team Effort,” Newsday, March 9, 1971.

[15] Keegan, Interview of Gavin.

[16] Thruelsen, The Grumman Story, 13-14.

[17] Ibid., 13-14; Gavin, “JGG Comments” regarding Kelly, Moon Lander, December 2001. Wright attended Harvard Business School. Kelly, Moon Lander, 225.

[18] Kelly, Moon Lander, 227.

[19] Gavin, dayplanner, April 14, 1970.

[20] Kelly, Moon Lander, 210. What distinguished Apollo 13 was the lack of occasional downtime to sleep.

[21] Statements by Gavin are quoted, respectively, from Martin Childs, “Joseph Gavin: Aerospace Engineer Who Played an Integral Part in the First Moon Landing,” The Independent, January 1, 2011, https://www.independent.co.uk/news/obituaries/joseph-gavin-aerospace-engineer-who-played-an-integral-part-in-the-first-moon-landing-2173400.html; and Gavin, interviewed by Rebecca Wright, NASA Johnson Space Center Oral History Project Oral History Transcript, Amherst, MA, January 10, 2003, https://historycollection.jsc.nasa.gov/JSCHistoryPortal/history/oral_histories/GavinJG/gavinjg.htm. [Hereafter: NASA Interview, 2003].

[22] Kelly, Moon Lander, 228-29.

[23] “Part 4: The Lunar Module.” Accordingly, Gavin tracked progress in his copy of the flight plan by noting days with a marker, as opposed to his normal practice of annotating extensively during the LM portion of the mission.

[24] NASA Interview, 2003.

[25] “Part 4: The Lunar Module.”

[26] The photo appears above the fold. “Alan B. Shepard, America’s First Man in Space, Applauds as He Watches the Apollo 13 Recovery on Television,” in “Astronauts Come Home Safely,” Washington Post, 18 April 1970, 1. This photo comprises the entire front page of “New York’s picture newspaper.” Daily News, April 18, 1970, 1.

[27] “Part 4: The Lunar Module.”

[28] “Special Honor Awards Ceremony,” NASA Manned Spacecraft Center, Houston, TX, February 1971; Bruce Lambert Jr., “Space Medal Winner Credits Team Effort,” Newsday, March 9, 1971. This was only the seventh such award since 1958.

[29] “Special Honor Awards Ceremony,” NASA Manned Spacecraft Center, Houston, TX, October 2, 1969.

[30] “Grumman President Honored,” Grumman Press Release LM72-5, November 2, 1972.

[31] “Grumman, Hedrick Get National Honors,” Grumman Plane News 33.7, April 15, 1974, 1.

[32] Neil A. Armstrong, “Joseph G. Gavin, JR. 1920-2010,” in Memorial Tributes: Volume 15 (Washington, DC: National Academies Press, 2011), 111-14, https://www.nap.edu/read/13160/chapter/21.

[33] Ross Daly, “Tech Hall of Fame Welcomes Four Newest Members,” Long Island Business News, March 16, 2007, http://libn.com/2007/03/16/tech-bytes-46/.

[34] Gavin followed the safety not only of American astronauts but also their Soviet counterparts. In his dayplanner on June 30, 1971, he recorded: “Russians announce death on return for Salyut [space station] cosmonauts.”

[35] Statement of Joseph G. Gavin, Jr., Senior Vice President, Grumman Aerospace Corporation, Before the Subcommittee on Manned Space Flight, Committee on Science and Astronautics, House of Representatives, Hon. Olin E. Teague, Chairman, March 14, 1972, 1.

[36] “Reacher for the Moon: Joseph Gleason Gavin Jr.,” New York Times, January 23, 1968, 10, https://www.nytimes.com/1968/01/23/archives/reacher-for-the-moon-joseph-gleason-gavin-jr.html.

[37] Richard Nixon, Letter to Llewellyn J. Evans, President, Grumman Corporation, May 26, 1970.

[38] Gavin, “The Apollo Lunar Module (LM): A Retrospective,” IAC-02-IAA.2.3.08, paper presented at 53rd International Astronautical Congress, Houston, TX, October 10-19, 2002, 3.

[39] Childs, “Joseph Gavin.” Gavin’s dayplanner contains numerous references to meeting and dining with astronauts.

[40] Keegan, Interview of Gavin.

[41] NASA Interview, 2003. See also “Grumman President L.J. Evans Welcomes Apollo 11 Astronauts,” Grumman Corporation Interim Report, September 30, 1969.

[42] “Grumman Course: Following the Fleet,” News Day, November 15, 1971, 21.

[43] NASA Interview, 2003; Keegan, Interview of Gavin.

[44] For Kelly quote, see Kelly, “Design Evolution of the Apollo Lunar Module,” 3. For similar wording, see “Apollo Navigation, Guidance, and Control Systems,” NASA-S-65-4336, 5/65, 11. For Gavin quote, see “The Lunar Module Story,” Grumman Corporation, 1989, https://www.youtube.com/watch?v=vjDdu7WzjQw.

[45] Gavin’s notation; Kelly, Moon Lander, 39.

[46] Keegan, Interview of Gavin; Henry S.F. Cooper, Jr., “A Reporter at Large: LM,” The New Yorker, January 11, 1969, 55; Fishman, One Giant Leap, 250.

[47] Gavin, notes for talk, “L.I. Apollo Anniversary,” 1989.

[48] O.S. (“Ozzie”) Williams, in Ross Fleisig and Lois Lovisolo, eds., “Lunar Module Remembrances,” AIAA 25th Anniversary of the First Manned Lunar Landing, Regional Conference, June 18, 1994, 40.

[49] “Welcome Home!” Grumman Plane News 29.9, May 11, 1970, 6.

[50] Williams, 40.

[51] John C. Bierwirth, Chairman, Report of Annual Meeting, Grumman Corporation, Bethpage, NY, April 18, 1985.

[52] On October 29, 1970, Gavin recorded in his dayplanner, he met Singaporean leader Lee Kuan Yew, then visiting regarding NASA’s High Energy Astronomy Observatory Program.

[53] Letter from The White House to Mr. and Mrs. J. Gavin, Jr., Grumman Aircraft Engineering Corporation, Bethpage, NY, postmarked August 2, 1969. Invitation to President’s Dinner Honoring Apollo 11 Astronauts, Century Plaza Hotel, Los Angeles, CA, August 13, 1969.

[54] On November 18, 1968, Gavin noted in his dayplanner, he lunched with Lindbergh, gave him a tour of the LM, and presented him a “booklet and pictures.”

[55] “Gavin, Joseph G. Jr.,” 50th Reunion Yearbook (Cambridge, MA: MIT Class of 1941, June 3-8, 1991).

[56] “2010 Eugene ‘Gene’ F. Kranz & Joseph E. Gavin, Jr.,” Godfrey L. Cabot Award, Aero Club of New England, https://www.acone.org/content.aspx?page_id=22&club_id=779885&module_id=284133#Kranz/Gavin. See also Janice Wood, “Cabot Award Winners Named,” General Aviation News, February 1, 2010, https://generalaviationnews.com/2010/02/01/cabot-award-winners-named/; “ACONE Presents Cabot Award to Joseph Gavin and Gene Kranz,” National Aeronautic Association, http://archive.constantcontact.com/fs091/1102200709681/archive/1103512417067.html.

[57] Porter Adams, “Aviation in Boston,” Fifty Years of Boston: A Memorial Volume Issued in Commemoration of the Tercentenary of 1930 (Boston: Subcommittee on Memorial History of the Boston Tercentenary Committee: 1932), 295-300.

[58] Keegan, Interview of Gavin.

[59] Gavin, “The Lunar Module Design and the Apollo Program,” annual Lester D. Gardner Lecture, Aeronautics and Astronautics Department, MIT, December 3, 1996, https://infinitehistory.mit.edu/video/joe-gavin-%e2%80%9c-lunar-module-design-and-apollo-program%e2%80%9d-mit-gardner-lecture-1231996.

[60] Gavin: “You don’t send it off unless…..you’re…willing to bet your best friend’s life on it, and not your own life because you’ve become awfully enthusiastic….” Author’s interview with Gavin, Amherst, MA, December 11, 1998.